Products

Direct-to-Chip Liquid Cooling

Liquid Cooling Systems

Direct-to-Chip Liquid Cooling

Motivair's Liquid Cooling Technology allows you to leverage increased processing power while using less energy and space than traditional air-cooled systems.

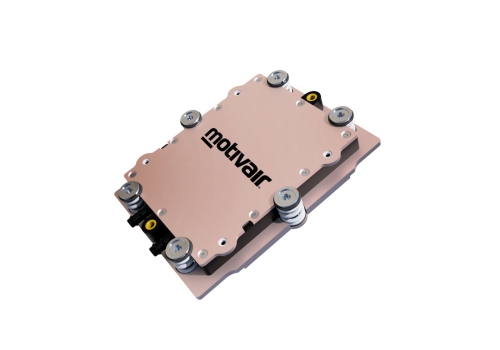

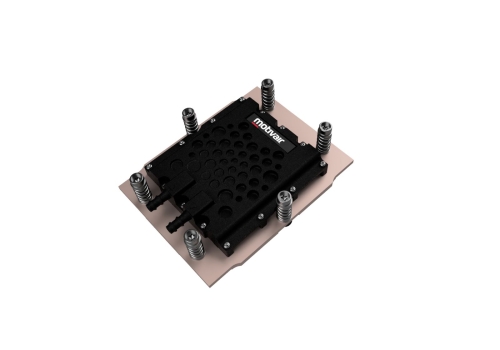

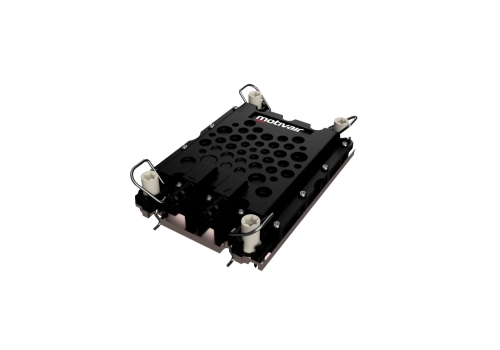

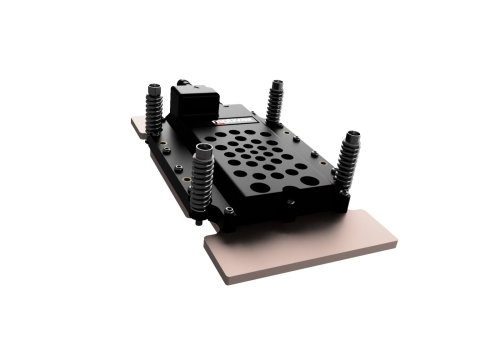

Dynamic® Cold Plates

Direct-to-Chip Liquid Cooling

Motivair's Dynamic® Cold Plate represents the next phase of delivering effective, reliable liquid cooling at the chip level.

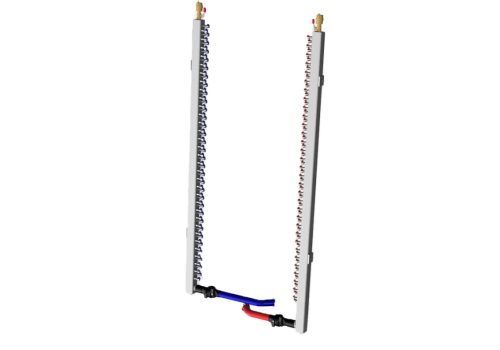

In-Rack Manifold

Direct-to-Chip Liquid Cooling

In-Rack Manifolds provide a common connection point between Motivair's Dynamic Cold Platesâ„¢ and the supply and return cooling infrastructure system or CDU.

Quick Connects

Direct-to-Chip Liquid Cooling

Quick Connects provide a seamless, make-or-break connection of water transfer lines for Motivair's Dynamic Cold Platesâ„¢

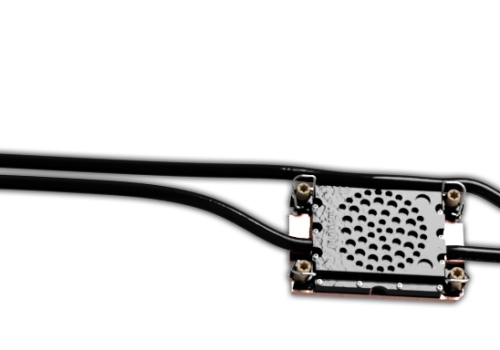

Cooling Loops

Direct-to-Chip Liquid Cooling

Cooling Loops tie Motivair's Dynamic Cold Plates into the liquid cooling system at the server. Motivair's cooling loops are designed specifically for each application, providing precise flow and

Hose Kits

Direct-to-Chip Liquid Cooling

Motivair hose kits provide a seamless connection from the in-rack manifold to the server and from the in-rack manifold to a Coolant Distribution Unit (CDU) or Heat Dissipation Unit (HDUâ„¢).

Motivair Dynamic® Cold Plate | AMD Instinct MI300A processors

Direct-to-Chip Liquid Cooling

Custom-engineered for AMD Instinct MI300A processors, Motivair's Dynamic® Cold Plates are designed to solve the most advanced thermal challenges.

Motivair Dynamic® Cold Plate | AMD SP3 Milan processors

Direct-to-Chip Liquid Cooling

Custom-engineered for AMD SP3 Milan processors, Motivair's Dynamic® Cold Plates are designed to solve the most advanced thermal challenges.

Motivair Dynamic® Cold Plate | AMD SP5 Genoa

Direct-to-Chip Liquid Cooling

Custom-engineered for AMD SP5 Genoa processors, Motivair's Dynamic® Cold Plates are designed to solve the most advanced thermal challenges.

Motivair Dynamic® Cold Plate | Intel Ice lake

Direct-to-Chip Liquid Cooling

Custom-engineered for Intel Ice lake Processors, Motivair's Dynamic® Cold Plates are designed to solve the most advanced thermal challenges.

Motivair Dynamic® Cold Plate | Intel Sapphire Rapids

Direct-to-Chip Liquid Cooling

Custom-engineered for Intel® Xeon® Scalable Processors, Motivair's Dynamic® Cold Plates are designed to solve the most advanced thermal challenges.

Motivair Dynamic® Cold Plates | NVIDIA SXM5

Direct-to-Chip Liquid Cooling

Custom-engineered for NVIDIA SXM5 processors, Motivair's Dynamic® Cold Plates are designed to solve the most advanced thermal challenges.

Data Center & IT Cooling

ChilledDoor®

Data Center & IT Cooling

Motivair's ChilledDoor Rack Cooling System is an active rear door heat exchanger capable of removing server densities up to 75kW per rack and 100% heat removal.

Coolant Distribution Units

Data Center & IT Cooling

Motivair's CDU controls and separates colder facility water supplies from the IT cooling infrastructure. It provides 100% comprehensive cooling up to 2.3MW (per unit).

In-Rack Coolant Distribution Unit

Data Center & IT Cooling

Motivair's In-Rack Coolant Distribution Unit (CDU), with redundant circulating pumps, features a 4U design, capable of placement in top or bottom of any standard 19†rack enclosure.

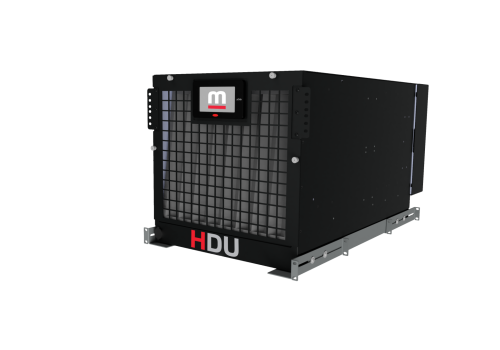

Heat Dissipation Unit | HDU™

Data Center & IT Cooling

Motivair's Heat Dissipation Unit (HDU™) is an active heat exchanger that converts liquid-cooled computer systems to air-cooled by rejecting heat to the server room.

In-Rack Heat Dissipation Unit (HDU™)

Data Center & IT Cooling

Motivair's In-Rack Heat Dissipation Unit (HDU™) circulates fluid to direct liquid-cooled cold plate technology, cooling designated chips and rejecting removed heat to the surrounding air

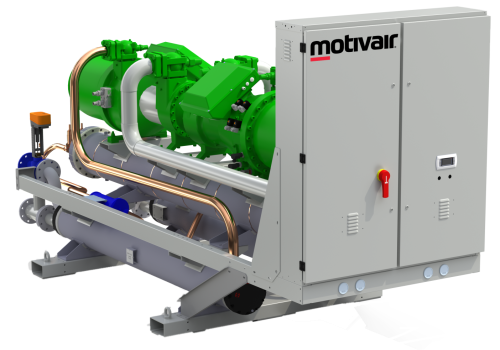

Thermal Management

Free-Cooling Chillers

Thermal Management

Motivair's Free-Cooling Chillers are designed to provide the owner with optimal, year-round performance in varying ambient temperatures.

Scroll Chillers

Thermal Management

Motivair's Air-Cooled Scroll Chillers are designed to provide the owner with optimal, year-round performance in varying ambient temperatures.

Industrial Process Chillers

Thermal Management

Industrial Process Chillers from Motivair offer a compact footprint with a standard primary pump, storage tank and powerful microprocessor controller.

Air-Cooled Chillers

Thermal Management

Motivair's Air-Cooled chillers were designed for industries and businesses that depend on reliable cooling for their critical operations and facilities.

Medical Chillers

Thermal Management

Motivair's Medical Chiller range operates in unison with the world's largest MRI, Linear Accelerator, and CT scanner manufacturers.

Compact Water-Cooled Chillers

Thermal Management

Motivair Water-Cooled Chillers are ideal for clients looking for a simple, compact, and reliable product to provide maximum equipment uptime and lowest TCO.

Pump Stations

Thermal Management

Motivair Pump Stations are designed, engineered, and manufactured to move fluids in industrial, institutional, and commercial markets.

Low Temperature Chillers

Thermal Management

Low Temperature Chillers from Motivair designed to cool process fluids between +32F and -25F with capacities from 5 to 300 Tons.